Syringe Plunger Moulds

Price 1000000 INR/ Unit

Syringe Plunger Moulds Specification

- Product Type

- Syringe Moulds

- Material

- EN8 Steel Mould base, C45/ P20 grade Core & Cavity plates

- Capacity

- 1500-10000 Pcs/min

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Dimension (L*W*H)

- 400x500x400 Millimeter (mm)

- Weight

- 600 Kilograms (kg)

- Color

- Gray

- Warranty

- 1 Year

Syringe Plunger Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- CHENNAI

- Supply Ability

- 6 Units Per Month

- Delivery Time

- 2 Months

- Packaging Details

- Wooden Box

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2015

About Syringe Plunger Moulds

Plastic injection molds designed exclusively for Syringe components. Mold sizes ranging from 8 cavity molds to 64 cavity molds. Components of Syringe: Barrel, Plunger and Gasket are designed as per international standards and ISO 7886-1 standard for syringes. The components are designed to optimize raw material usage to give best cost effectiveness in syringe manufacturing.

Main Technical Parameters

- Component Type 1ml 2ml 3ml 5ml 10ml 20ml 50ml syringe Barrel Plunger and Gasket

- Productivity No of cavities ranging from 8 cavity moulds to 48 cavity moulds 1500 pcshour to 10000 pcshour

- Material EN8 Steel Mould base C45 P20 grade Core Cavity plates HDS H11H13 Hardened Core Cavity inserts

- Feeding System Cold runner mould with auto degating

- Cycle Time 1518 seconds per shot

- Mould Life 5 million cycles

- Plastic Material Poly propylene random copolymer for Barrel High Density Polyethylene Poly propylene homo polymer for Plunger Thermoplastic Elastomer Block for Gasket

- Overall dimension L x W x H 400x500x400mm

- Weight 600 Kgs

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Syringe Making Machine Category

Fully Automatic Syringe Printing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 year

Material : Stainless Steel

Product Type : Fully Automatic Syringe Printing Machine

Semi-Automatic Syringe Assembly Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Material : Stainless Steel (SS)

Product Type : Syringe Assembly Machine

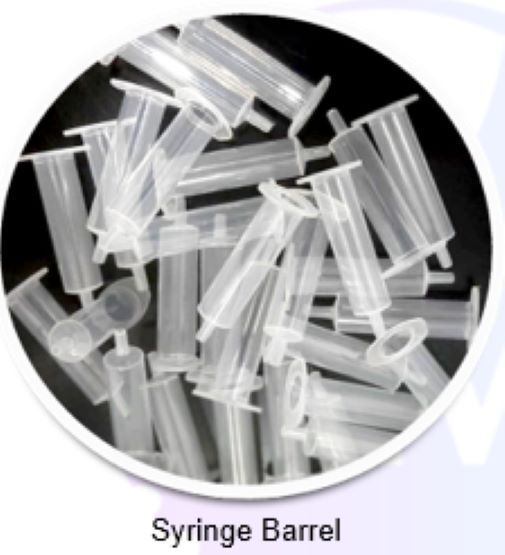

Syringe Barrel Moulds

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 Year

Material : EN8 Steel Mould base, A C45/ P20 grade Core & Cavity plates

Product Type : Syringe Moulds

Syringe Gasket Moulds

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 Year

Material : EN8 Steel Mould base, C45/ P20 grade Core & Cavity plates

Product Type : Syringe Moulds

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry