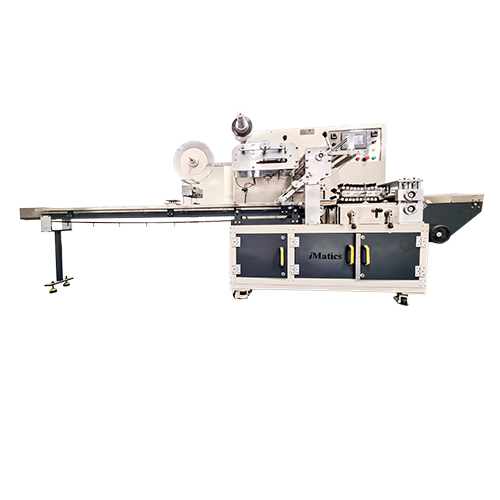

Semi-Automatic Syringe Barrel Printing Machine

Price 600000 INR/ Unit

Semi-Automatic Syringe Barrel Printing Machine Specification

- Product Type

- Semi-Automatic Syringe Barrel Printing Machine

- Material

- Stainless Steel (SS)

- Capacity

- 6,000-8,000 Pcs/min

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Voltage

- 440 Volt (v)

- Power

- 1500 Watt (w)

- Dimension (L*W*H)

- 1600x1000x1450 Millimeter (mm)

- Weight

- 500 Kilograms (kg)

- Color

- Silver

- Warranty

- 1 Year

Semi-Automatic Syringe Barrel Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- CHENNAI

- Supply Ability

- 6 Units Per Year

- Delivery Time

- 2 Months

- Packaging Details

- Wooden box

- Main Domestic Market

- All India

- Certifications

- ISO 9000:2015

About Semi-Automatic Syringe Barrel Printing Machine

Our Semi-Automatic Syringe Barrel Printing Machine is an innovative solution for precise printing on syringe barrels in the pharmaceutical and medical sectors. We are providing it as a manufacturer, supplier and trader for years. Printing Efficiency: This machine's innovative technology enables fast and precise printing, maximizing manufacturing productivity. The user-friendly control panel makes operation simple, reducing operator training time. Printing settings may be easily adjusted for varied syringe barrel sizes, forms, and designs, providing adaptability for a variety of goods. It produces clear and durable prints with precise ink application, fulfilling strict quality standards. Semi-automatic handling simplifies the printing process, decreasing manual intervention and increasing production. Our Syringe Barrel Printing Machine is made of durable materials to provide long-lasting performance and low maintenance.

Brief Introduction-

The IMPAR series rotary semi-automatic printing machine manual feeding systems can be integrated with the accepted moulded syringe barrel into the machine.

Advantages-Semi-automatic Rotary Printing Machine of Syringe barrel has adopted the variable-frequency governor and high efficiency and energy saving. With safety cover, stop running immediately when open it. The machine has several advantages: The production efficiency for the rotary printing machine is savaral times more than traditional screen printing. The printing area has adopted a drum-type silicon rubber wheels and embossing seal, which can effectively reduce the wastage of printing ink. With characteristics of smooth gear drive and low noise and Accurate positioning, high pass - rate of production.

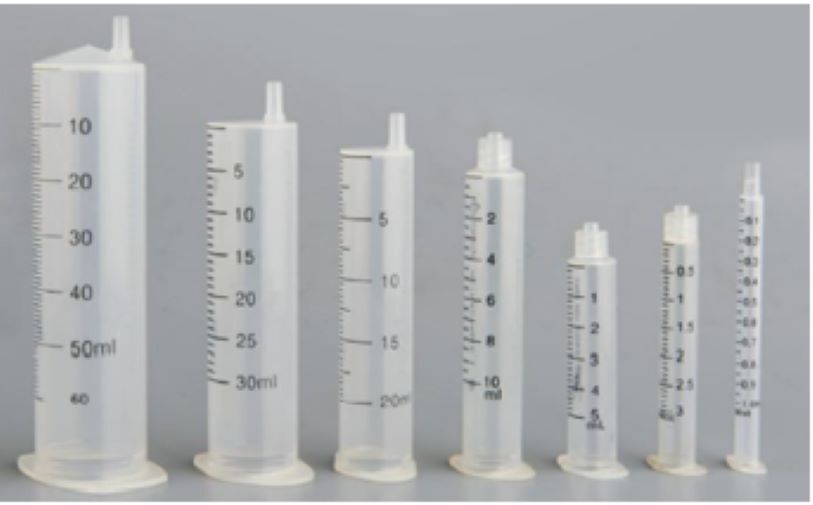

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Syringe Making Machine Category

Fully Automatic Syringe Barrel Printing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel (SS)

Product Type : Syringe Barrel Printing Machine

Warranty : 1 Year

Automatic Grade : Automatic

Fully Automatic Syringe Printing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Fully Automatic Syringe Printing Machine

Warranty : 1 year

Automatic Grade : Automatic

Syringe Plunger Moulds

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : EN8 Steel Mould base, C45/ P20 grade Core & Cavity plates

Product Type : Syringe Moulds

Warranty : 1 Year

Automatic Grade : Automatic

Disposable Syringe Making Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Disposable Syringe Making Machine

Warranty : Yes

Automatic Grade : SemiAutomatic

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry