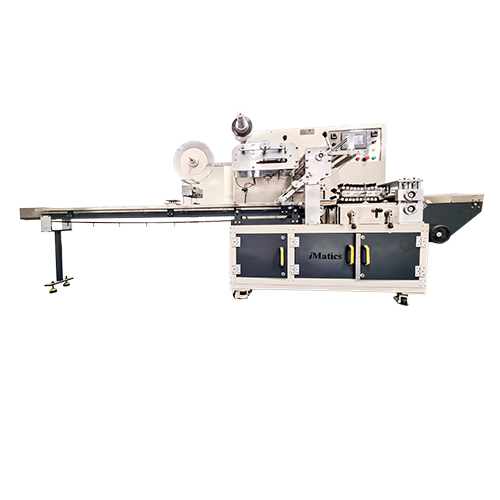

Fully Automatic Needle Assembly Machine

Price 10000000 INR/ Unit

Fully Automatic Needle Assembly Machine Specification

- Product Type

- Needle Assembly Machine

- Material

- Steel

- Capacity

- 40,000 to 50,000 Pcs/min

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Voltage

- 440 Volt (v)

- Power

- 1700 Watt (w)

- Dimension (L*W*H)

- 7700x3100x1550 Millimeter (mm)

- Weight

- 3000 Kilograms (kg)

- Color

- Silver

- Warranty

- 1 Year

Fully Automatic Needle Assembly Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- CHENNAI

- Supply Ability

- 6 Units Per Year

- Delivery Time

- 2 Months

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa, Australia, Central America, North America, South America, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Fully Automatic Needle Assembly Machine

Fully automatic needle assembly machine is designed to assemble parts like cannulaneedle hun and cap into a complete needle for Bulk Needle and Syringe assembly Advantages It can assemble various size of needle by adjustment of cap inserting part and replacement of needle inserting jig Adjustment of dispensing quantity of epoxy resin in accordance with the require specification is available Fully automatic Needle Assembling System Hub Cannula Cap Self checking for defective badness product.

Main Technical Parameters:

- Structure: SS machine structure

- Automation System: Pneumatics and Electrical actuators

- Controls: PLC control with HMI

- Drives: Variable frequency drive speed control

- Stations: Hub feeder & loading, Corona discharge treatment, Cannula feeding, Epoxy application, heat curing tunnel, Silicon Coating, Blockage & Needle tip Inspection, rejected needle ejector, cap feeder & Caping and finished product ejector.

- Motors & Drives: AC Bonfiglioli drive with gear box.

- Parts feeding: Automatic using customized feeder.

- Conveyor: Chain conveyor

- Air Consumption: 900LPM

- Production Capacity: 40,000 to 50,000 pcs/h

- Power: 17Kw, three phase, 440V

- Overall dimension: (L x W x H) 7700x3100x1550mm

- Weight: 3000 Kgs

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Syringe Making Machine Category

Fully Automatic Syringe Barrel Printing Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Syringe Barrel Printing Machine

Automatic Grade : Automatic

Material : Stainless Steel (SS)

Color : Silver

Fully Automatic Syringe Assembly Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Syringe Assembly Machine

Automatic Grade : Automatic

Material : Stainless Steel (SS)

Color : Silver

Blister Packing Machine with Automatic Syringe Loader/feeder:

Price 3500000 INR

Minimum Order Quantity : 1 Number

Product Type : Blister Packing Machine with Automatic Syringe Loader/Feeder

Automatic Grade : Other, Fully Automatic

Material : Stainless Steel (SUS304)

Color : Silver

Disposable Syringe Making Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Disposable Syringe Making Machine

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Color : Gray & White

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry