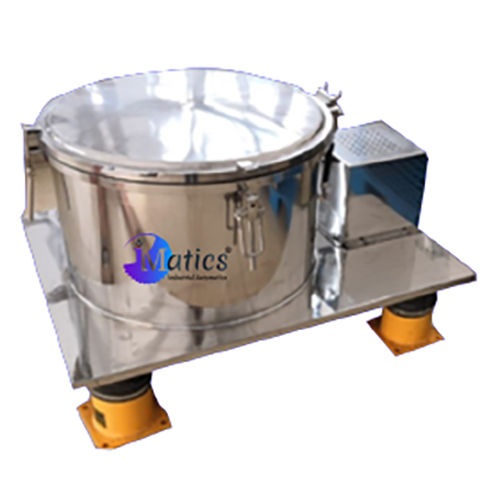

Blood Collection Tube Vacuuming and Cap Pressing Machine

Price 1000000 INR/ Unit

Blood Collection Tube Vacuuming and Cap Pressing Machine Specification

- Product Type

- Vacuum Blood Collection Tubes

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Voltage

- 220 Volt (v)

- Power

- 1500 Watt (w)

- Dimension (L*W*H)

- 600x500x1700 Millimeter (mm)

- Color

- Silver

- Warranty

- 1 Year

Blood Collection Tube Vacuuming and Cap Pressing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- CHENNAI

- Supply Ability

- 10 Units Per Year

- Delivery Time

- 45 Days

- Packaging Details

- Wooden Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Blood Collection Tube Vacuuming and Cap Pressing Machine

This equipment is used for blood collection tube vacuuming. Inside of the tube will automatically produce a certain negative pressure.

Working Principle -

Manually put the mould rack with full tubes and caps into the mould rack moving platform press the start button

the mould rack moving device automatically moves the mould rack to the vacuum chamber vacuumize and press the stopper after the vacuum is completed, the mould rack automatically moves out of the vacuum chamber to the mould moving platform manually take out the mould rack that has finished vacuumizing, thus completing a vacuumizing operation. The vacuum control system adopts precise proportional control, and the vacuum is stable and accurate without interference from external factors.

Servo proportional technology: directly input the corresponding vacuum value on the touch screen, you can get the corresponding vacuum degree product, the set value is almost the same as the displayed value, ensuring the vacuum repeatability.

Database system: A powerful database function that can store the vacuum required for various altitudes, different blood collections, and different product specifications. It has production information storage function for post management.

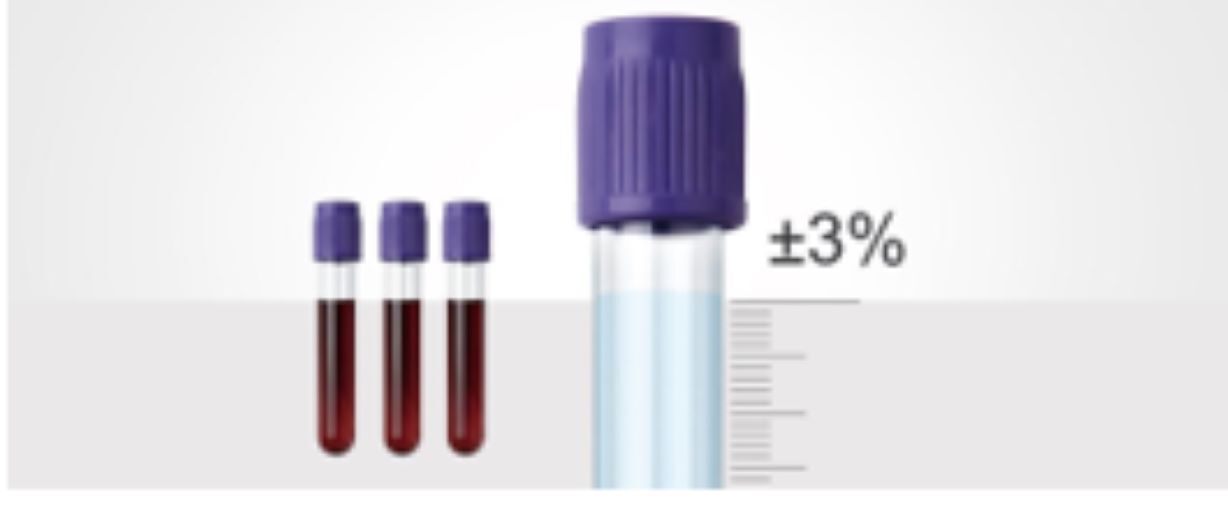

100pcs/cycle, 10 times digital control vacuum system

Tolerance of vacuum

Product Parameters

- Production Capacity: 8000 to 10000 pcs per h

- Vacuum degree accuracy: less than3%

- Tube Size: Dia13x75mm, Dia13x100mm, Dia16x100mm

- Air Consumption: 0.2 m3 per min

- Overall dimension L x W x H: 600x500x1700mm

Efficient Blood Tube Preparation

This semi-automatic machine streamlines the vacuuming and capping of blood collection tubes, significantly reducing manual handling and increasing productivity in laboratories and medical facilities. Its stainless steel build ensures durability and hygiene, while the PLC control system enhances operational accuracy.

Reliable and Adaptable Design

With PLC-controlled operations and a sturdy stainless steel frame, the machine can be easily integrated into existing lab workflows. The compact dimensions (600x500x1700 mm) make it suitable for spaces with limited room. Its one-year warranty provides added assurance for users looking for long-term reliability.

FAQs of Blood Collection Tube Vacuuming and Cap Pressing Machine:

Q: How does the Blood Collection Tube Vacuuming and Cap Pressing Machine operate?

A: The machine operates with a semi-automatic mechanism, utilizing a PLC control system for automated vacuuming and cap pressing of blood collection tubes. Users simply load the tubes, set operational parameters, and supervise the procedure, allowing for efficient and consistent tube preparation.Q: What materials are used in the construction of this machine?

A: This machine is constructed from high-quality stainless steel, offering corrosion resistance and ease of cleaning. This makes it suitable for medical and laboratory environments that require stringent hygiene standards.Q: When is it recommended to use this machine in the blood collection process?

A: The machine is best utilized during the tube preparation phase, before blood is collected from patients. It ensures tubes are properly vacuumed and capped, ready for immediate use in clinical or diagnostic laboratories.Q: Where can the Blood Collection Tube Vacuuming and Cap Pressing Machine be installed?

A: Designed with compact dimensions (600x500x1700 mm), the machine can be conveniently installed in hospitals, diagnostic labs, blood banks, or any facility involved in blood sample processing.Q: What is the process involved in vacuuming and capping the tubes?

A: The process begins with loading the tubes into the machine. The PLC system then initiates vacuuming to remove air, followed by automatic cap pressing. This ensures tubes are sealed with the correct pressure and vacuum level for preservation of blood samples.Q: How does the use of this machine benefit laboratories and users?

A: The semi-automatic function reduces manual labor, minimizes errors, and improves throughput. Its robust design and easy operation enhance laboratory efficiency while maintaining precise and repeatable tube preparation results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Blood Collection Tube Assembly Machines Category

Blood Collection Tube Labelling Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Automatic Grade : Automatic

Color : Silver

Material : Stainless Steel

Centrifuge Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Automatic Grade : SemiAutomatic

Color : Silver

Material : Stainless Steel

Separation Gel Filling Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Automatic Grade : SemiAutomatic

Color : Silver

Material : Stainless Steel

Blood Collection Tube Cleaning and Drying Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Automatic Grade : SemiAutomatic

Color : Silver

Material : Stainless Steel

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry